Concentrol’s Food Processing Aids Division has the mission of offering chemical solutions for the conservation, protection, elaboration and finishing of food products. One of the sectors in which Concentrol products are applied is cheese production. The company elaborates essential coatings in its manufacture, a fact that gives us an added value worldwide in the cheese sector.

The manufacture of cheese consists of different stages, being in the maturation phase where Concentrol can contribute its knowledge, proposals and solutions.

The company’s research and development experts evaluate the entire process of preparing cheeses, to offer solutions in accordance with the demand of producers and the market.

The cheese making process

The first step in the manufacture of cheese is the treatment of milk, consisting of different stages. First, it is hygienized eliminating unwanted particles and homogenized to provide it with concrete fat parameters.

At this point the milk can be subjected to pasteurization, a heat treatment used to eliminate microbes and other pathogens. It is possible to follow the process with raw milk, being common in long-curing cheeses. Subsequently, milk is cooled to the temperature to grow lactic initiators (30-32ºC). Finally, the milk is placed in tanks at a certain temperature where microorganisms, initiators or lactic ferments are added, depending on the type of cheese that is going to be developed (milk pre-maturation stage).

Subsequently, the curdling process is carried out, where milk passes from liquid to solid state. This process can be carried out by the action of a proteolytic enzyme (enzymatic curdling), by milk acidification up to pH = 4.6 (acid curdling) or by the action of both (mixed curdling).

Once the milk is curdled, the whey removal process is undertaken, which consists of different stages. Initially, the curd is cut by blades to divide it into smaller portions called “curd grains”. The cut will be greater or lesser depending on the amount of whey that you want to eliminate. Subsequently, the product is heated, constantly stirring so that the grains created in the cut are not united again and can easily expel whey through all their faces.

After this stage, moulds are filled and will later be subjected or not under pressure for the final elimination of more whey, which allows the adaptation of mould forms. Depending on the pressure exerted, we refer to them as pressed paste cheeses.

At this point, if the curd arrives with a lot of whey, the grains merge with each other in a homogeneous way. If the curd arrives more “dry” the cheese cut will provide some holes. To continue eliminating the lactoserum from the inside of the cheese, give flavour, form the rind and give protection against certain microorganisms, the salting of cheese by immersion in brine is performed. The concentration of salt and the immersion time depends on the type of cheese wanted.

Once the necessary time in the brine bath has elapsed, the cheese is removed from it and the excess brine that the cheese has absorbed is removed. To do this, there are two methods:

– Airing: Traditional method that consists of leaving cheese between 1 and 3 days on grilles located in special chillers with determined ambient temperature and humidity (13-15ºC and 75% relative humidity), depending on the type of cheese. During this stage, turning the cheese helps the drying and exudation of most of the brine.

– Air blowing: Industrial method that replaces the airing process in industrial facilities to optimize cheese manufacturing time. Once out of the brine, the cheese passes under dry air blowers, which eliminate a substantial part of the brine, especially the superficial amount.

The brine that is inside the cheese and cannot be removed by the processes described above will be gradually eliminated during the curing process.

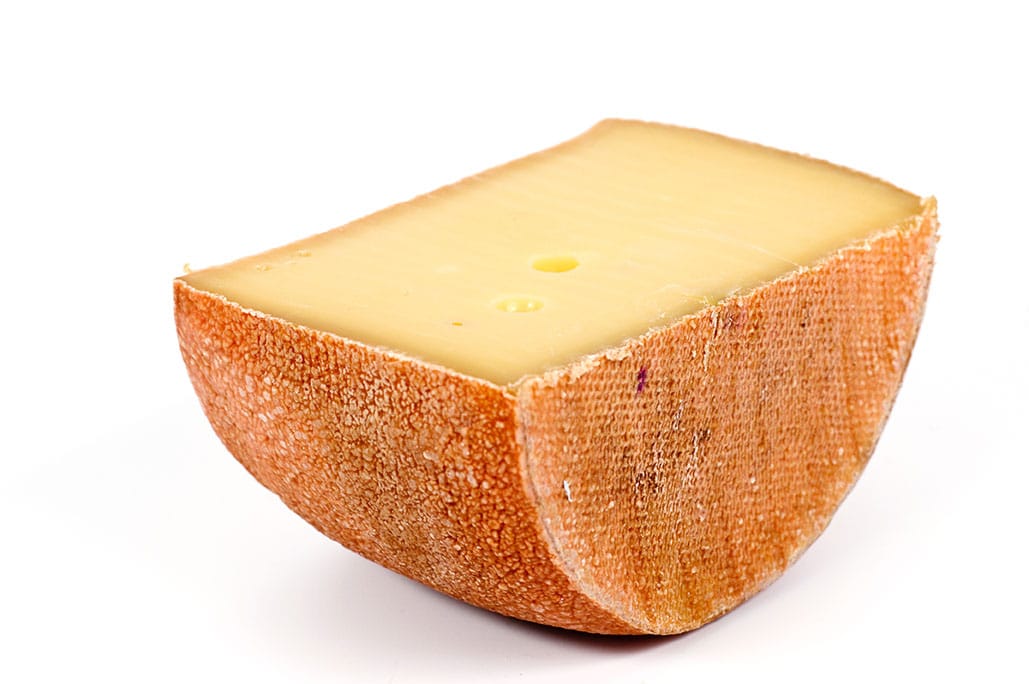

The next stage in the cheese manufacturing chain is the treatment of cheese with a protective coating. This avoids unwanted growth of moulds and yeasts and regulates the loss of cheese water during the curing process. There are two types of coatings: plastic and natural (based on rubber, cellulose and other natural products). Coatings can be applied by immersion bath, spray (airbrush gun), brushes or manually.

Once the coating has been applied, the taste, smell and texture of a cheese depend on the maturation process. This phase consists of a slow drying of the cheese with a controlled water loss, where cheese evolves in different stages.

The coating and its properties

The coating plays a very important role in the quality and appearance of cheese. This can be applied on the rind before, during and/or after the maturation process. A coating mainly has two functions, avoiding the appearance of moulds and yeasts in the food and regulating the cheese’s loss of water during the curing process, reducing food weight loss. In addition, it improves the final appearance of cheese.

There are two types of cheese coatings, natural coatings and plastic. Natural coatings are formulated to be edible with cheese, offer greater breathability that accelerates maturation and gives it an artisanal and natural appearance. Plastic coatings, on the other hand, form a non-edible film on the surface of the cheese, totally non-toxic, that does not penetrate the product and regulates the process of maturation without affecting the smell or taste of the treated piece.

At Concentrol we develop plastic coatings and high quality natural coatings that act before, during and after the maturation stage, regulating the loss of moisture and protecting cheese against unwanted growth of microorganisms such as moulds and yeasts. They also protect the cheese from material damage during transport and allow a specific final colour or texture appearance.

If during the cheese curing process coatings without preservatives are used, naturally there is mould growth on its surface. However, avoiding the growth of mould on cheese is a complicated task, since the use of preservatives for this category of food is limited according to European regulations (regulation (EU) 1333/2008).

The main demand of the cheese sector is to avoid the proliferation of mould on cheese and on this challenge Concentrol’s research work is developed.

Before the commercialization of cheeses, in many cases a final coloured coverage is applied. This treatment avoids the growth of moulds and yeasts once the cheese is in the market and gives a final finish to the food, distinctive of each manufacturer, avoiding damage by friction and blows on its rind.

Currently, cheeses are sold packaged in a vacuum or in the protective atmosphere system to minimize the possible growth of mould. However, there is a significant percentage of cheese that is sold packaged in cardboard boxes. Precisely, it is in the latter case where the final application of a paint containing preservatives becomes more important.

Concentrol bets day by day for the research of new chemical solutions that allow us to cover the needs of the population and cheese producers around the world.